What is 3D printing?

- 3D printing, also known as additive manufacturing, is the process of creating three-dimensional objects from a digital file. It involves building the object layer by layer using materials such as plastics, metals, and ceramics. The process begins by designing the object using computer-aided design (CAD) software, which creates a digital model. The digital model is then sliced into many thin layers, typically ranging from 0.05 to 0.3 millimetres in thickness, depending on the 3D printer and the desired level of detail. The 3D printer then prints each layer sequentially to create the final object.

Benefits:

- One of the main advantages of 3D printing is its ability to reduce production time and cost. Traditional manufacturing processes can be time-consuming and expensive, involving multiple steps and the use of specialized tools. 3D printing simplifies the process by directly creating the final product from a digital model, reducing the number of steps involved and the time required to produce the final product.

- With the help of 3D printing, it is possible to create complex geometries and customized products. 3D printing can produce intricate designs and shapes that would be difficult or impossible to create with traditional manufacturing methods. This opens up new possibilities for product innovation and customization, allowing for the creation of products tailored to specific customer needs.

- 3D printing is also a cost-effective option for small-scale production runs. Traditional manufacturing methods require expensive equipment and machinery, making them less feasible for smaller production runs. 3D printing eliminates this barrier by allowing for the production of small quantities of products without the need for expensive equipment.

- Parts with varying thicknesses and densities can be produced with 3D printing. This allows for the creation of products that are lighter and more efficient than their traditionally manufactured counterparts.

- 3D printing can reduce waste by eliminating the need for assembly and enabling the production of parts with minimal material usage.

Potential applications:

- Healthcare: 3D printing has already been used to produce patient-specific implants, prosthetics, and surgical tools, leading to better outcomes and reduced costs.

- Aerospace: 3D printing enables the production of lightweight, high-strength parts and components, reducing the weight of aircraft and spacecraft and improving their performance. China’s ambitious space exploration plans have taken another fascinating turn as it looks to expand the use of 3D printing technology to construct buildings on the moon. The country’s space agency has unveiled the next phase of its lunar mission, which involves establishing a long-term human presence on the moon. As part of this, China is looking to explore the potential of 3D printing to create infrastructure on the moon.

- Automotive industry: 3D printing can be used to produce complex geometries and customized parts with relative ease, reducing costs and manufacturing time in the production process. This can lead to more efficient and flexible manufacturing processes.

- Consumer goods: 3D printing can be used to produce customized and personalized products, allowing for more individualized and unique consumer experiences. This can lead to increased customer loyalty and satisfaction, as well as new opportunities for small-scale producers and entrepreneurs.

Impact on the future of manufacturing:

- Decentralization: 3D printing has the potential to decentralize manufacturing by enabling the production of goods closer to their point of use, reducing transportation costs and production time.

- Customization: 3D printing allows for the creation of highly customized products and small-scale production runs that would be difficult or impossible with traditional methods. This opens up new business models and markets, as products can be tailored to the needs and preferences of individual customers.

- Rapid prototyping: It enables designers and engineers to quickly produce and test prototypes. This will allow for more rapid iteration and innovation in the product development process, leading to better products and faster time to bring them into the market.

- Sustainability: Traditional manufacturing methods often involve producing excess material or creating products with standard sizes and shapes, which can lead to a significant amount of waste. However, 3D printing enables manufacturers to produce only the necessary amount of material for each product, reducing waste and saving resources. This is because 3D printing produces products layer by layer, adding material only where it is needed to create the final product.

Conclusion:

3D printing represents a significant shift in the manufacturing industry, with the potential to disrupt traditional methods and transform the way goods are produced. However, 3D printing can also disrupt traditional manufacturing industries, leading to job losses in some sectors and creating opportunities in others. The technology could enable new forms of decentralized and on-demand manufacturing, challenging traditional supply chains and business models. Overall, the impact of 3D printing on the future of manufacturing is significant, and the technology is poised to play a major role in shaping the industry in the coming years.

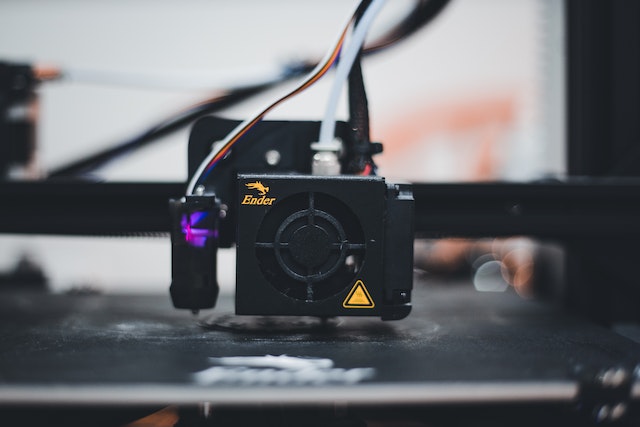

Photo by Erik Mclean

Your Turn…

What’s your take on the recession? Express your point of view through the comment section below. And subscribe to our blog to read answers to the trending GD topics.

References:

Copyright @ Group Discussion Ideas.